Elmet Technologies (formerly H.C. Starck Solutions) supplies high-performance tungsten balance weights for balancing and vibration control applications into the aerospace and defense markets. Explore our high-density tungsten balance weights here.

Elmet Technologies (formerly H.C. Starck Solutions) manufactures a variety of semi-finished or finished balls, spheres, and cubes from a range of materials, including high density tungsten alloys.

Elmet Technologies (formerly H.C. Starck Solutions) produces advanced bearing parts capable of withstanding extreme temperatures and loading conditions without succumbing to thermal or mechanical degradation. Our unmatched experience in precision machining refractory components to extreme tolerances ensures consistent, repeatable performance.

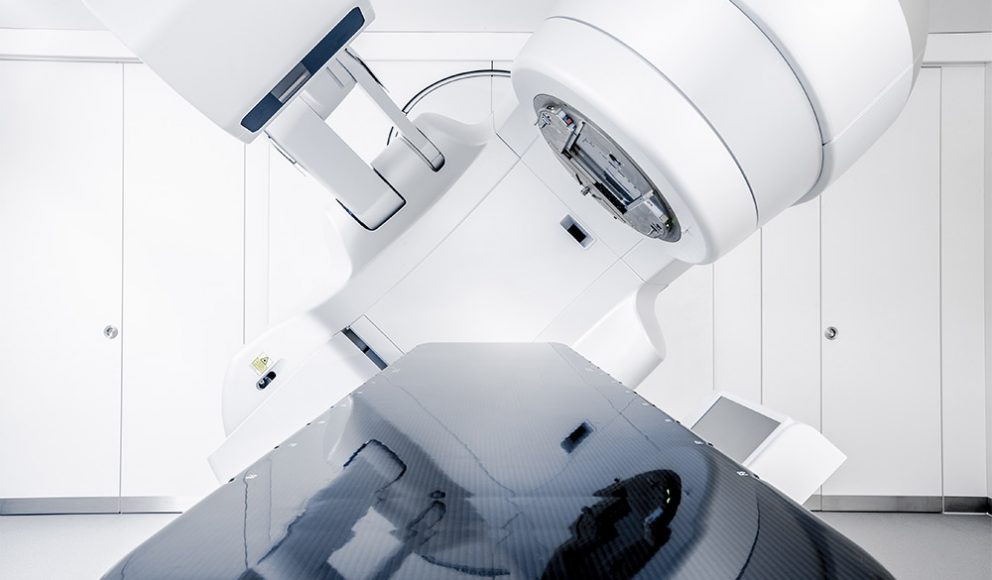

Tungsten and molybdenum collimators and anti-scatter grids, are critical components for radiation management in computerized tomography (CT) scanning and radiotherapy. Elmet Technologies (formerly H.C. Starck Solutions) manufactures and supplies collimators with superb attenuation characteristics for use in all medical applications.

Elmet Technologies (formerly H.C. Starck Solutions) offers an extensive range of pre-cut discs and squares as well as the ability to cut customized discs in various sizes from molybdenum, tungsten, and their alloys.

Elmet Technologies (formerly H.C. Starck Solutions) can provide custom dimensions and designs for evaporation boats to customer specifications. They provide even and controlled heating when switched on to vaporize the more volatile substrates.

Elmet Technologies’ (formerly H.C. Starck Solutions) furnace boats are made of molybdenum alloys and have exceptional retention of their shape at annealing temperatures which often exceed 800°C or 1472°F.

Some advantages of Elmet Technologies’ (formerly H.C. Starck Solutions) glass melting electrodes include higher energy efficiency, lower capital cost per unit of capacity, and more control over glass melting applications.

Effective thermal management components, like those produced by Elmet Technologies’ (formerly H.C. Starck Solutions), use cost-effective, composite materials that possess high thermal conductivity and low thermal expansion.

Elmet Technologies (formerly H.C. Starck Solutions) specializes in the production of refractory alloy heating elements for superior performance in all furnace applications.

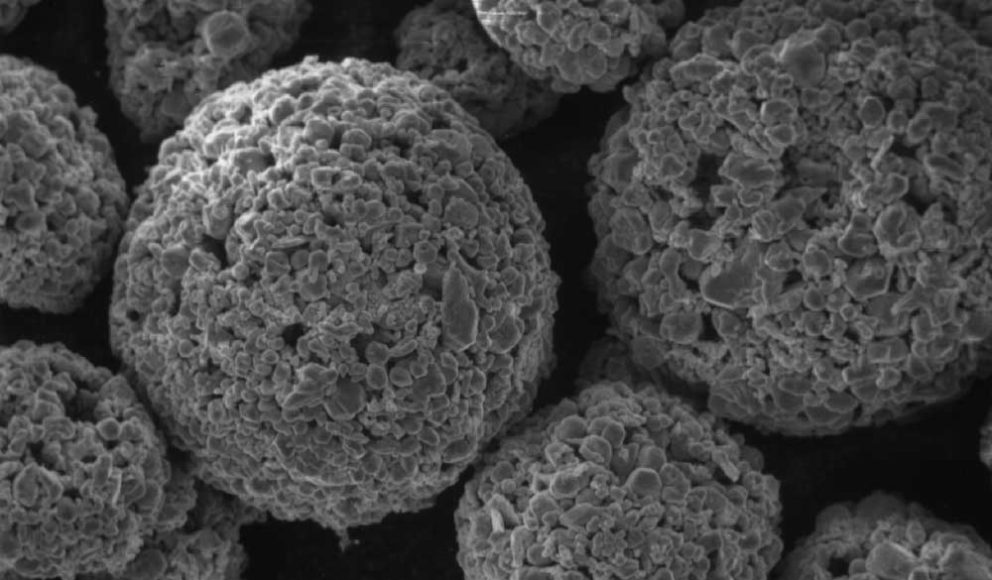

With a mastery of metallurgic processing and unsurpassed technical expertise, Elmet Technologies (formerly H.C. Starck Solutions) can reliably meet and exceed customer expectations and market requirements with a suite of tailor-made, high-performance powders suitable for a wide range of market sectors.

Elmet Technologies (formerly H.C. Starck Solutions) can provide customer-specific high-quality furnace components and fixtures for high-temperature furnaces.

Elmet Technologies (formerly H.C. Starck Solutions) has customized superior die alloys to improve the forging and diffusion bonding process and result in high quality forged products.

Elmet Technologies (formerly H.C. Starck Solutions) provides advanced engineered components for radiation safety and materials transport. They can supply 3D printed collimator parts function as gamma camera collimators and PET SEPTA plates for shielding in PET cameras as well as parts for radiation shielding and isotope containers.

Elmet Technologies (formerly H.C. Starck Solutions) has a range of advanced materials that can be fabricated into geometries suitable for high-performance ordnance and munitions, including explosively formed penetrators and shaped charge liners, as well as forging blanks from refractory materials.

Elmet Technologies (formerly H.C. Starck Solutions) is a global supplier of high-performance sheet, plate, and foil based on precision refractory metals and their alloys.

Elmet Technologies (formerly H.C. Starck Solutions) has a wealth of experience in the design and manufacture of materials to create coatings with exceptional adherence. This results in final products with outstanding bonding, oxidation resistance, and coefficients of thermal expansion perfectly tailored to the substrate material.

Elmet Technologies (formerly H.C. Starck Solutions) uses an array of innovative manufacturing techniques to produce powder and wire feedstocks that offer world-class performance with highly spherical powder morphology, excellent flowability, exceptional reproducibility, and high purity levels.

Our refractory metals for shielding have densities that can range from 10.2 – 18.5g/cc. As a result, these materials can be 1.5 times as effective as lead and provide extremely efficient protection, particularly where space is limited.

Elmet Technologies’ (formerly H.C. Starck Solutions) high performance sintering trays are valuable in multiple industries because they possess superior structural strength and can be manipulated at elevated sintering temperatures.

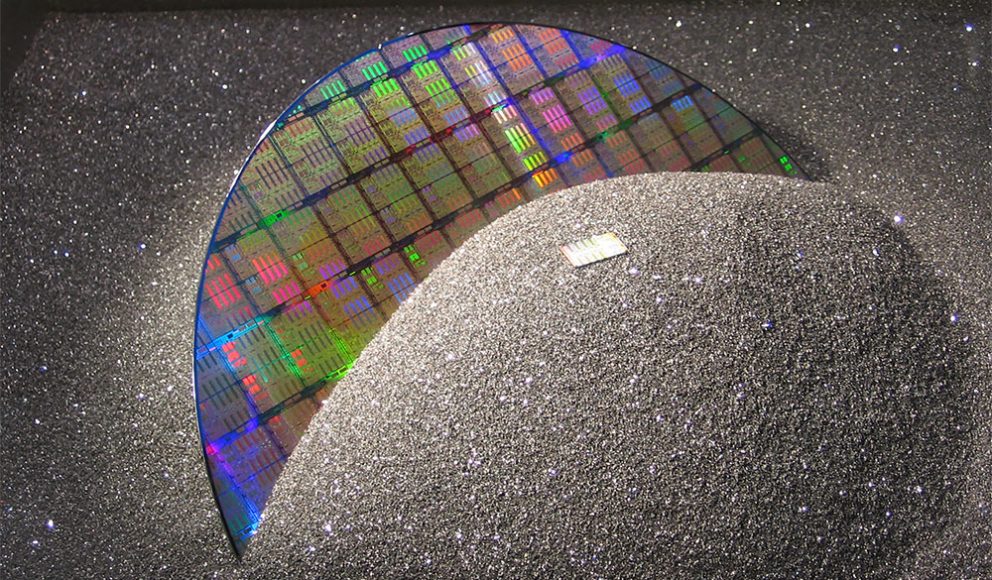

The number one goal of Elmet Technologies (formerly H.C. Starck Solutions) is to manufacture materials for sputtering targets that produce high quality, uniform coatings while ensuring cost effective target utilization.

Elmet Technologies’ (formerly H.C. Starck Solutions) molybdenum thermal spray powders enable our customers to protect their products against the detrimental effects of erosion, wear and corrosion.

Vibration dampeners by Elmet Technologies (formerly H.C. Starck Solutions) effectively diminish vibrational oscillations from functioning mechanical systems in machinery.We possesses over 50 years of expertise in areas of customizable alloys, making our vibration dampeners both high-performing and ideal for your application.