Applications

Market Segment

Materials

Applications

In recent years, metal additive manufacturing has evolved beyond rapid prototyping applications and is now used to manufacture a range of complex, high-performance engineering components. AM techniques are supremely versatile: as well as providing a means to produce geometrically complex pieces, they can provide an economic route for lower volume products and dramatically improve material utilization in expensive materials.

With AM technology improving rapidly, the pool of possible AM applications increases every day. Elmet Technologies (formerly H.C. Starck Solutions) refractory metal powders are currently used to produce components for biomedical, propulsion and heat management systems, among others.

Materials and Specifications

We specialize in the production of refractory metal powders, in both pure and alloyed forms.

| Property | Unit | Nb | Mo | Ta | W |

|---|---|---|---|---|---|

| Purity | % | >99.95 | >99.95 | >99.95 | >99.95 |

| Mean Particle Size D50 |

μm | 20-30 | 20-30 | 20-30 | 20-30 |

| D10/D90 | μm | 10/40 | 10/40 | 10/40 | 10/40 |

| Bulk density | g/cc | 4 | 5 | 8 | 10 |

| Hall Flow | s/50g | 14-16 | 8-10 | 5-9 | 5-8 |

| Oxygen | ppm | 1500 | 400 | 300 | 250 |

Our customized portfolio includes a range of alloys, including tantalum alloys (Ta-3W, Ta-10W), molybdenum alloys (TZM, Mo-La, Mo-Re), tungsten alloys (WHA, W-Re), and niobium alloys (Nb C-103).

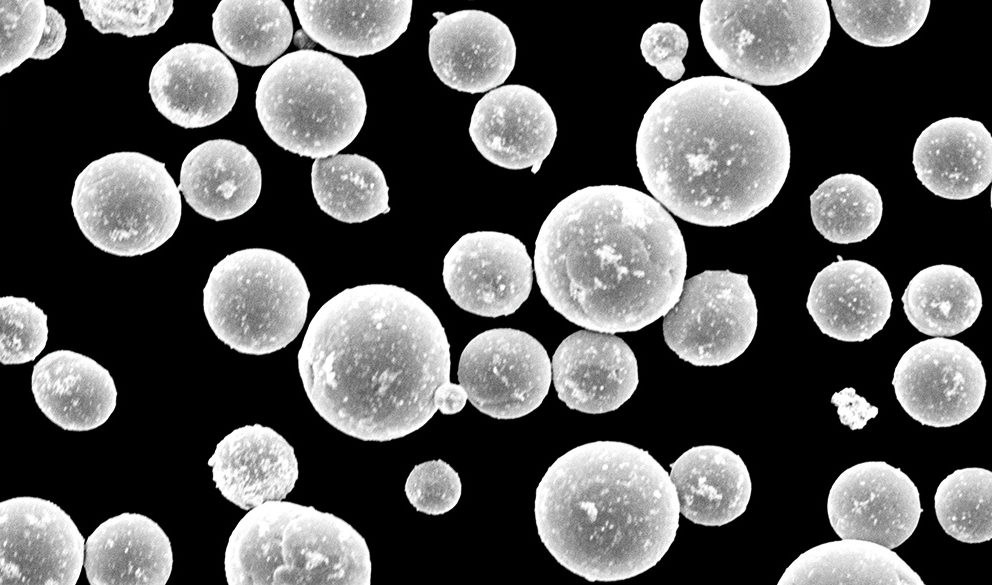

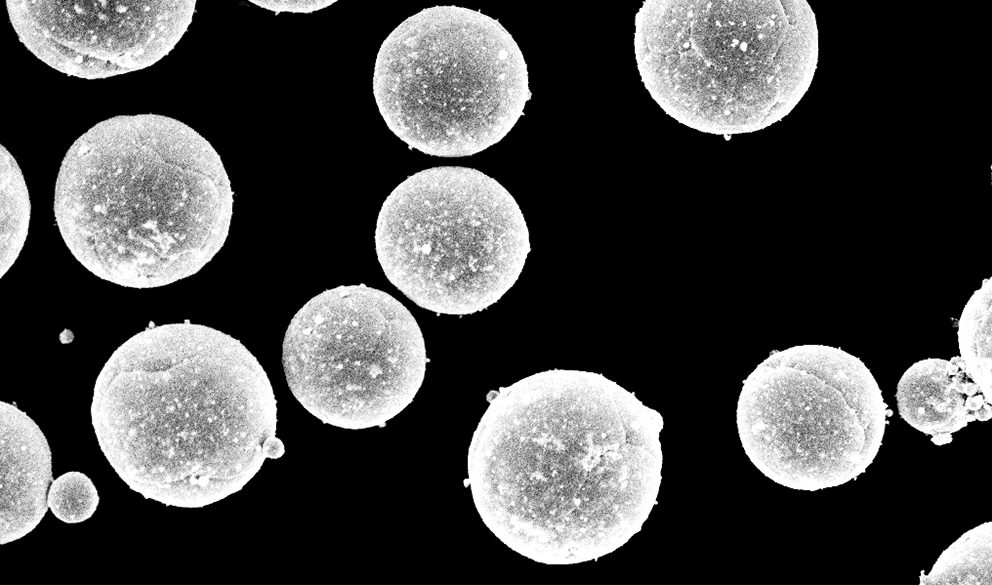

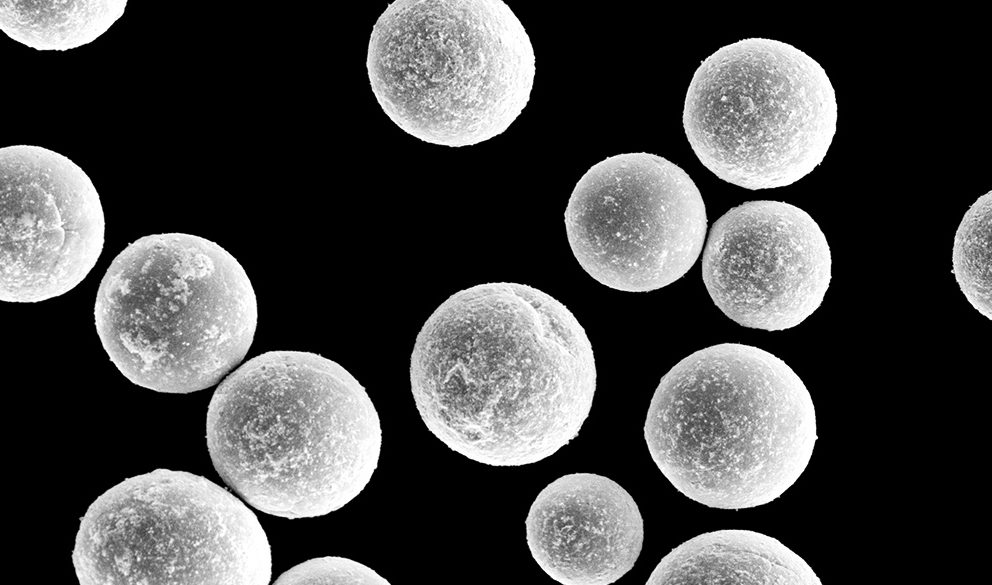

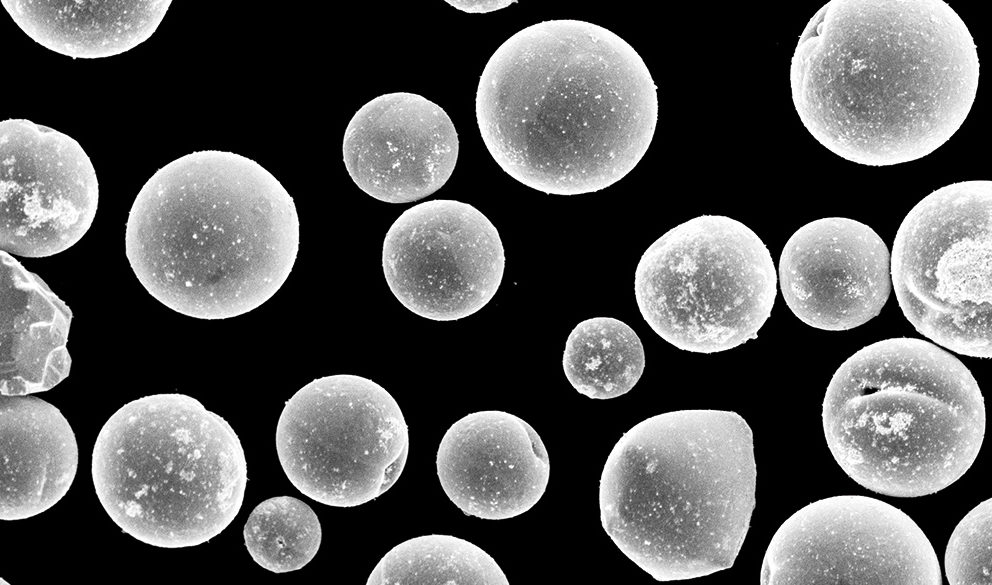

Our considerable R&D capabilities enable us to continuously develop new custom alloys and methods to solve customer problems. H.C. Starck Solutions refractory metal powders offer unique advantages:

- High purity

- High bulk density

- Spherical or flake powder morphology

- Exceptional flowability

- Low oxygen content

- PSD optimized for specific printing methods

- Volumes from laboratory to production scale

With our unique understanding of refractory metals, we can help customers find the optimal materials and AM methods to meet their application requirements. To find out more about our high-performance powders for additive manufacturing, get in touch with a member of the Elmet Technologies (formerly H.C. Starck Solutions) team today.

Related Datasheets

Related Brochures

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.