Applications

Market Segment

Materials

Application

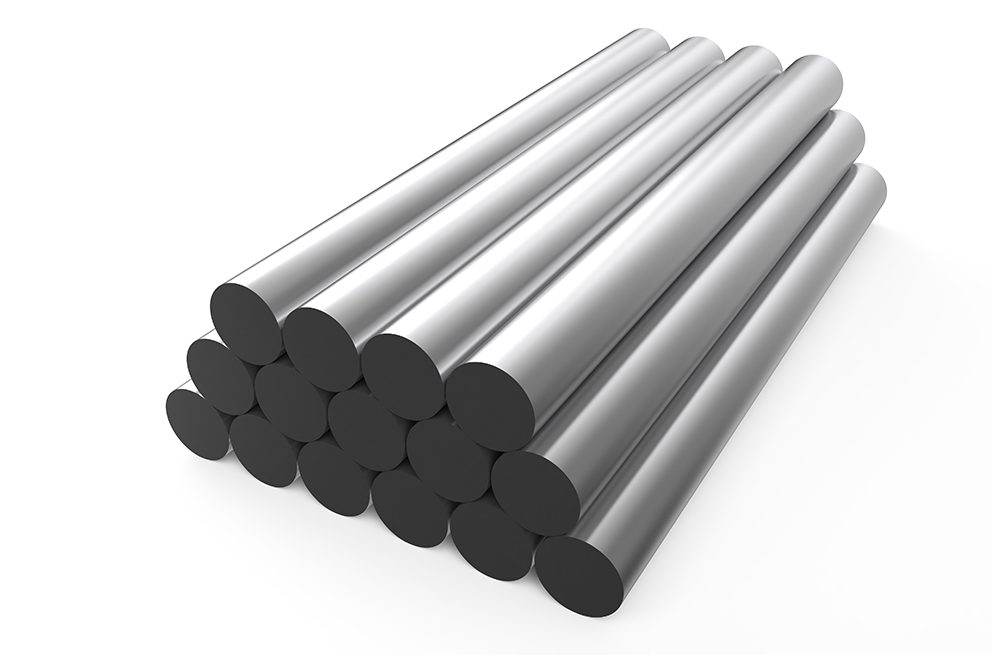

As one of the primary feedstock forms for metal processing industries, bars and rods from Elmet Technologies (formerly H.C. Starck Solutions) are used wherever high purity and workability are critical.

We produce bars and rods from a range of refractory metals and alloys, offering corrosion resistance, superior mechanical strength, and heat resistance for the most demanding use cases.

Materials & Specifications

Molybdenum

Our arc-melting and powder metallurgy processes deliver bars and rods in a variety of molybdenum formulations; from 99.97% pure molybdenum (from 1/8in to 4in diameter) to alloys including Mo30W (1/8in to 3 ¼in), TZM (1/8in to 3 ½in (90mm), MHC (¼into 3 ½in) and many others.

Tungsten

We have been manufacturing tungsten products for over 100 years and provide a range of tungsten heavy alloy bars and rods for engineering, aerospace, and medical technology applications.

Use the form below to request a quote, or get in touch with our sales team to find out more about our range of materials and manufacturing capabilities for metal bars and rods.

Related Datasheets

Related Brochures

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.