Our Unique Product & Service Portfolio

Elmet Technologies (formerly H.C. Starck Solutions) offers a diverse portfolio of highest quality refractory metal products. From powders and semi-finished parts including plate, sheet, foil, coil, tube, rod, disks, and bars to finished fabrications and additively manufactured components – we cover it all!

Our toll services like extrusion, forging, hot, and cold rolling round out our family of products and services.

Industries We Supply To

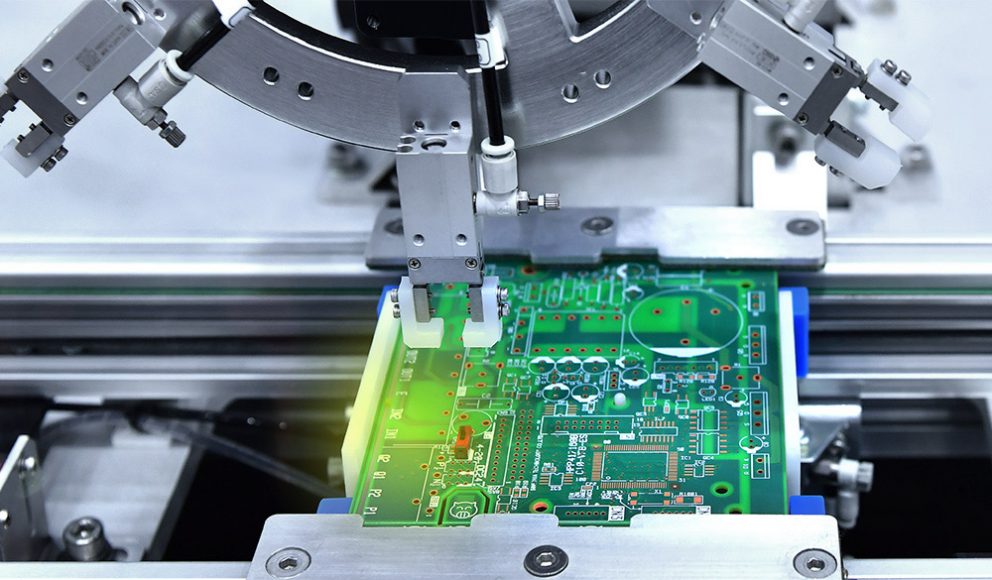

Elmet Technologies’ (formerly H.C. Starck Solutions) sputtering materials are used in a variety of electronic applications, including data storage, fiber optics, flat panel displays, large area coatings, and semiconductors.

Our tungsten alloys are used to precisely balance aircraft and helicopters. These control weights can be found on surfaces of ailerons, elevators, rudder sections, helicopter rotor blades, and cockpit instrumentation.

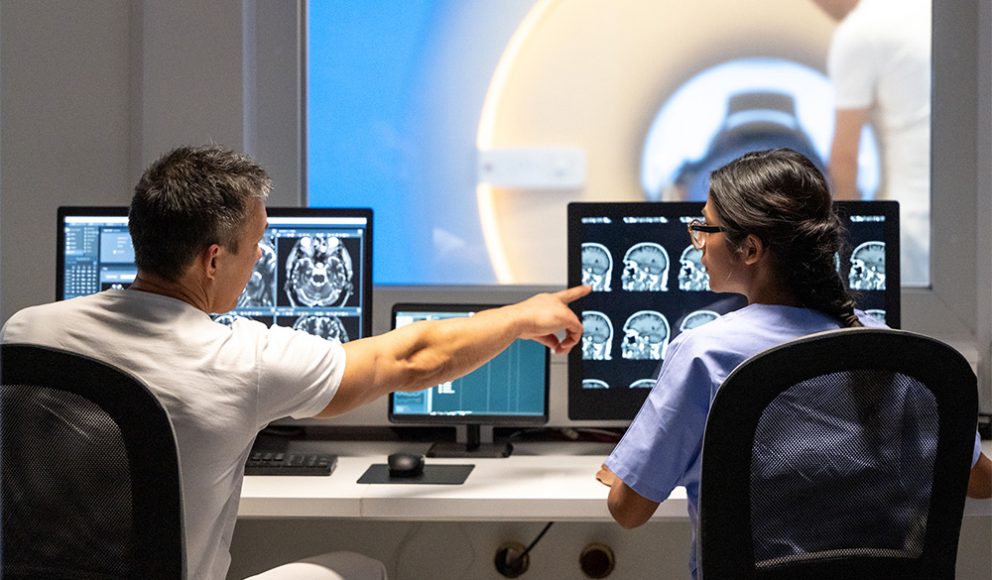

Whether it is glass making, heat treating of medical and aerospace products, or supplying power conversion for energy and transportation, our fabricated products offer customized solutions.

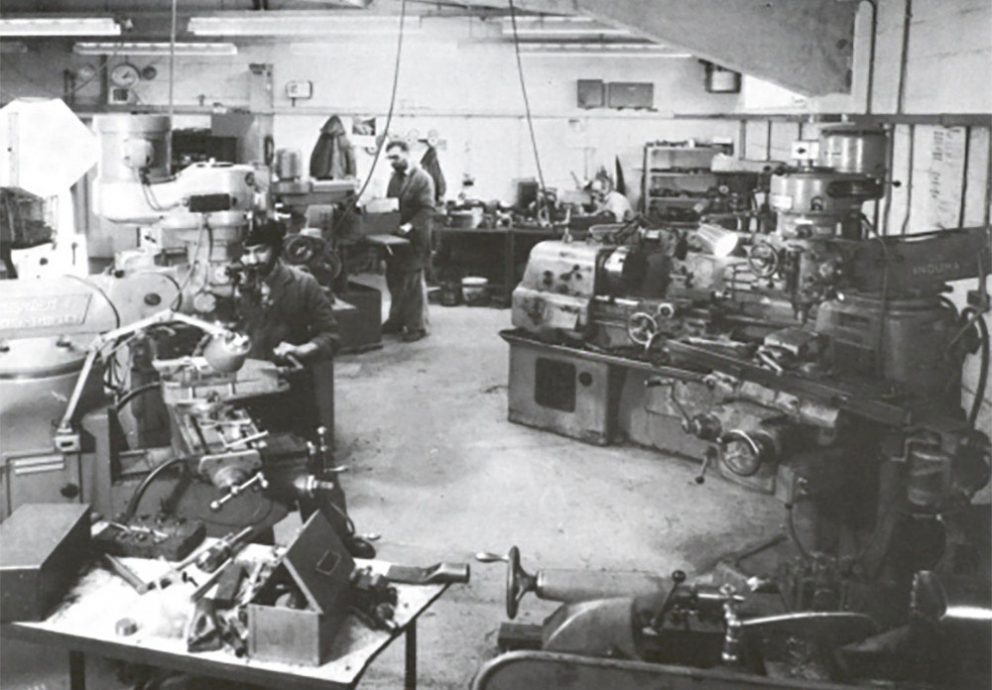

100 Years of Refractory Metals Expertise

In 2020, Elmet Technologies (formerly H.C. Starck Solutions) is proudly celebrating our centenary, marking 100 years of refractory metals expertise and metallurgical excellence. A centenary is always worth celebrating – explore our history to find out more about how our products and materials impacted the 20th Century.

In 2023, Elmet Technologies acquired H.C. Starck Solutions. The company is now known as Elmet Technologies with facilities in Coldwater (MI), Euclid (OH), and Lewiston (ME).

Our Service Portfolio

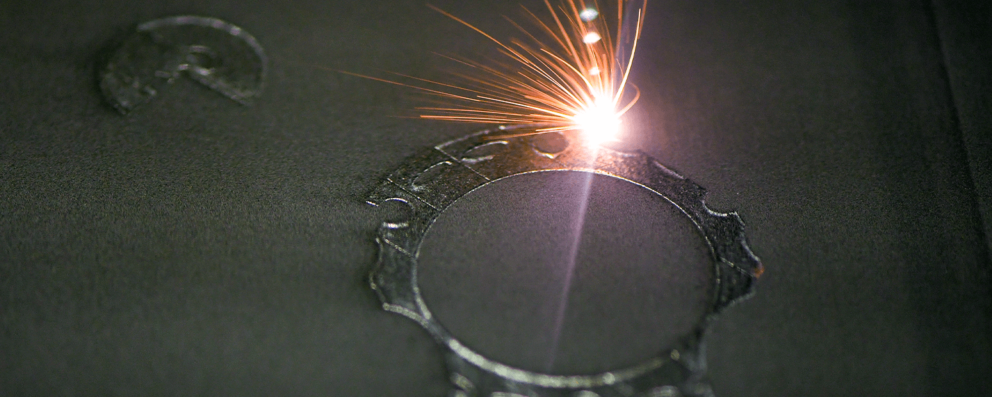

Additive manufacturing (AM), also known as 3D printing, has been discovered as a real “game changer” because it opens completely new possibilities for many industries. The innovative technology leads to entirely new ways of manufacturing custom-made components and highly complex elements that have been unthinkable to produce with conventional technologies before.

Our range of flexibility encompasses almost any size and near-net-shape in almost any metal you can imagine. We are one of the few suppliers worldwide able to extrude pipe with integral flanges. Efficient use of materials, close attention to quality and a flexible production program mean that we can often deliver a first class product precisely to customer specifications in as little as two weeks.

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.