Applications

Market Segment

Materials

Application

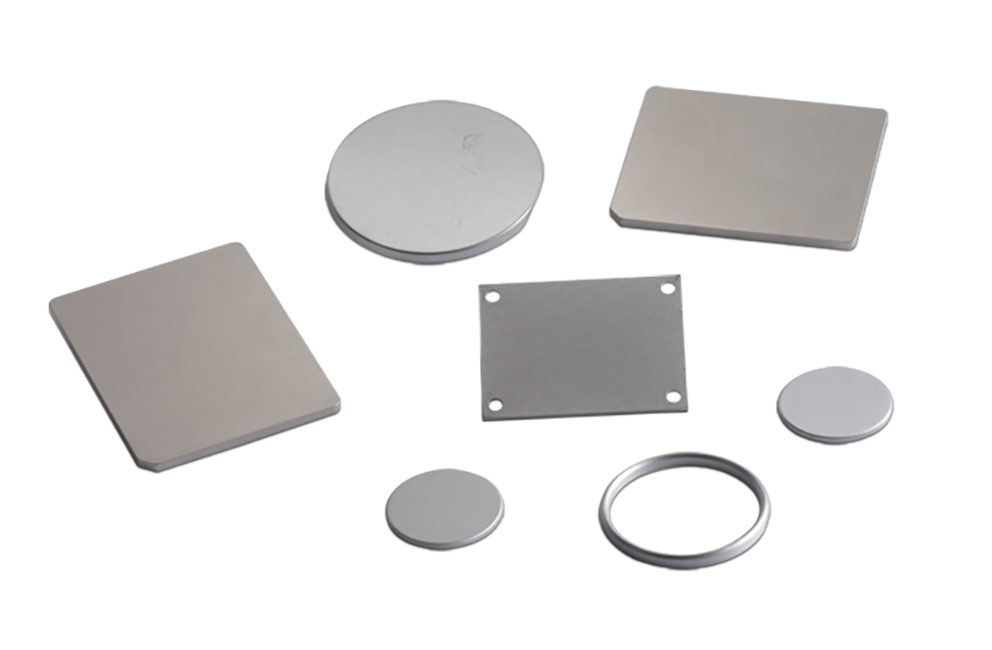

Our thermal management components can be tailored to meet specific requirements of cooling a diverse array of high performing electronics. For example, our molybdenum semiconductor base plates are used for high-power electronic devices, like thyristors, transistors, and rectifier diodes.

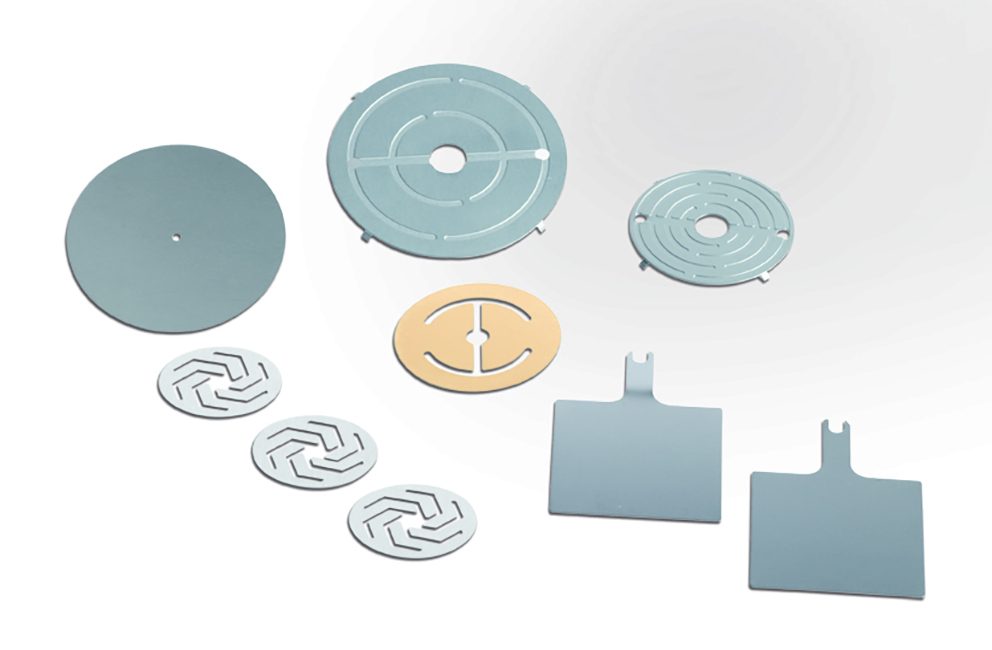

Our molybdenum-copper composites are most suitable for IGBT power modules and modern GaN or SiC MOSFET power transistors used in inverters of electric cars. The thermal properties of our molybdenum-copper laminates (CMC) can be customized for specific requirements of high-frequency electronics such as Si-LDMOS transistors or GaN HEMT packages, as well as flip chip packages for CPU and other micro-electronic devices.

Our tungsten-copper composites provide high thermal conductivity and perfect expansion matching with compound semiconductors used in opto-electronics and photonic devices, like laser diodes and HHL fibre-optic packages.

Market Segment

The electronics packaging market depends on highly efficient engineered thermal materials providing excellent heat spreading capability to maintain operable temperatures. It also depends on controlled CTE for a long lifetime and high-reliability of the devices.

Highly integrated electronic devices, using high power-density GaN and SiC semiconductors, require improved package designs with efficient cooling performance. As electronic devices become more portable with increased functionalities and thus increased heat production, cooling technologies need to keep pace.

Materials & Specifications

Heat spreader and semiconductor base plates must use materials that disperse heat quicker and more efficiently, whilst at the same time matching the thermal expansion behavior of the active device as well as other ceramic or metal packaging components.

This is why Elmet Technologies (formerly H.C. Starck Solutions) uses composite materials based on refractory metals and high-purity copper. This combination brings together the thermo-mechanical advantages of both materials, namely high thermal and electrical conductivity and low thermal expansion. This allows for the creation of high-temperature package components capable of handling high heat fluxes and power densities in the advanced electronics market.

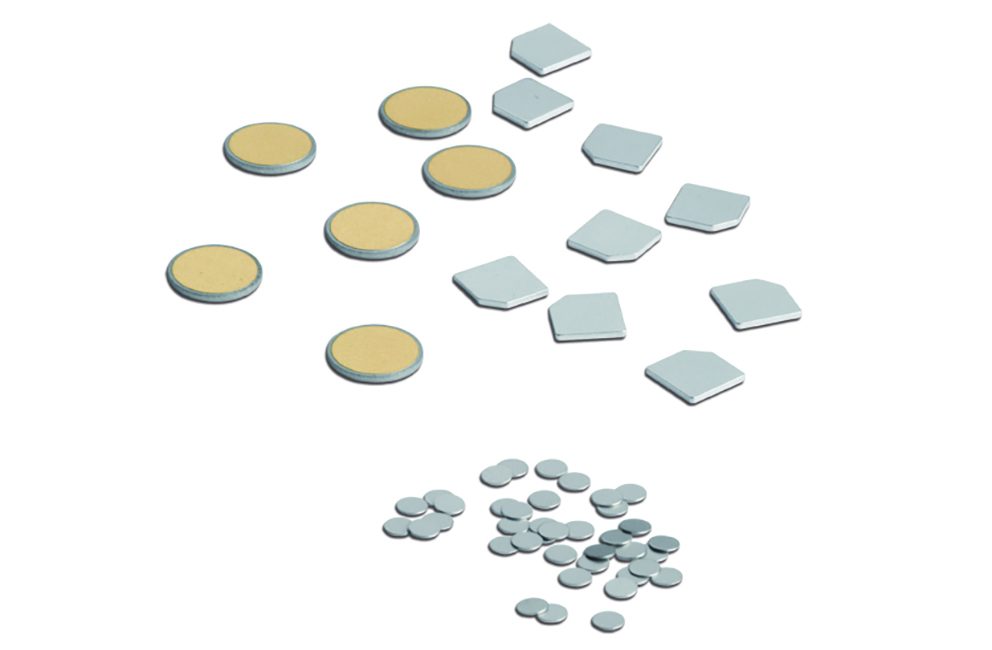

Many of our heat sinks are made of molybdenum and tungsten-copper composites specifically designed for high heat dissipation and controlled thermal expansion. Ratios of refractory metals to copper are customizable in our heat spreaders and base plates, providing the ideal combination of low CTE and high thermal conductivity for unique heat regulation needs.

Elmet Technologies (formerly H.C. Starck Solutions) also produces copper and nickel-clad molybdenum laminate heat sink materials that provide high in-plane heat spreading and good matching of thermal expansion with a range of semiconductor wafers. These materials can be produced in high volumes and have been approved for numerous military and aerospace applications.

Elmet Technologies’ (formerly H.C. Starck Solutions) possesses decades of expertise in developing efficient materials for advanced heat regulation in electronics. If you have any questions or want to learn more about our high temperature heat sinks, please do not hesitate to fill out the RFQ form on-page. You can also contact our highly experienced sales representatives on our Customer Support and Engineering Team.

Related Brochures

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.