A Brief History of H.C. Starck

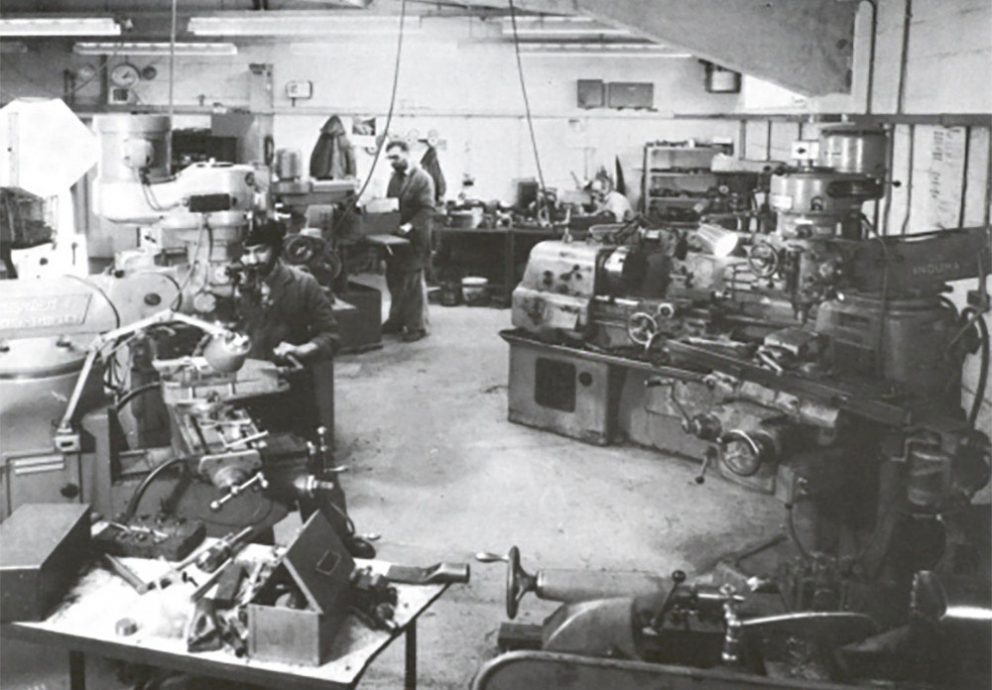

In 1920, Hermann C. Starck set up a modest trading company in his own name in his native Germany. Primarily dealing in metals and ores, this fast-growing business expanded into the US with a New York facility by 1925. Within a single decade, H.C. Starck had added chemical and metallurgical manufacturing to its portfolio from the main facility in Goslar, Germany. This established the foundation of our forthcoming expertise in refractory metals and technical materials.

As part of a phase of strategic diversification, H.C. Starck acquired the US-based National Research Corporation (NRC) in the 1970s. This merger was the foundation for the division now widely known as H.C. Starck Solutions.

Since the 1970s, H.C. Starck Solutions focused on organic growth through acquisitions and joint ventures. This smart approach established us as a powerhouse in industrial manufacturing, particularly in the realm of refractory metal powders and parts. It was this period when we established our core competencies with the key refractory metals tantalum (Ta), molybdenum (Mo), tungsten (W), and niobium (Nb).

Under the ownership of Bayer AG – and later Carlyle and Advent Groups – our expansion comprised multiple, major operations in Europe, North America, and Asia. This expansive global footprint would have been impossible to achieve prior to the latter portion of the 20th Century. Over the last decade, we have followed a policy of concentrating our assets into focussed divisions that better serve a diverse customer base. Some of these have been divested while others have been strategically added.

H.C. Starck Solutions (now Elmet Technologies) now spans three manufacturing plants in the United States, and our technologies are integrated into numerous technologies characteristic of the late 20th Century. Commercial airplanes, semiconductor devices, medical imaging equipment, even modern production lines utilize tailored H.C. Starck Solutions (now Elmet Technologies) products based on high-performance refractory metals. Our products have helped illuminate millions of homes and have traveled as far as the moon. In the near future, our refractory metal solutions for the aerospace industry are expected to reach the surface of Mars.

In 2023, Elmet Technologies acquired H.C. Starck Solutions to form a global leader in tungsten and molybdenum materials and components. The combined company offers a broadened portfolio for customers and plans growth across its three U.S. facilities in Coldwater (MI), Euclid (OH), and Lewiston (ME).

-

1920

Humble Beginnings

Founded in Berlin (Germany), by Hermann C. Starck as a trading company for metals and ores.

-

1925

Into the USA

Foundation of H.C. Starck Inc., in New York.

-

1945

Patented Products

First patents for high-purity tantalum and niobium metal powders are filed; expansion and comprehensive modernization of reduction capacities for tungsten and molybdenum metal powders.

-

1987

NRC

The US based National Research Corporation started their research in tantalum and niobium in 1959 in Newton, MA. After holding a 50% share in the company since 1976, H.C. Starck fully acquires NRC.

-

2000

Further Acquisition

H.C. Starck acquires a majority stake in the American CSM Group, and integrates the business as its Fabricated Products (FPR) area, headquartered in Newton (US).

-

2018

Sale of divisions

As part of H.C. Starck`s strategic development of ownership, the division STC was sold to Höganäs AB and the division Ta&Nb was sold to JX Nippon Mining & Metals Corporation.

-

2019

H.C. Starck Solutions

H.C. Starck’s Fabricated Products (FPR) division rebrands itself and becomes H.C. Starck High Performance Metal Solutions (H.C. Starck Solutions).

-

2023

H.C. Starck Solutions Americas Acquired by Elmet Technologies

The acquisition forms a global leader in tungsten and molybdenum materials and components. The combined company offers a broadened portfolio for customers and plans growth across its 3 U.S. facilities in Coldwater (MI), Euclid (OH), and Lewiston (ME). The company is renamed Elmet Technologies.

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.