Application

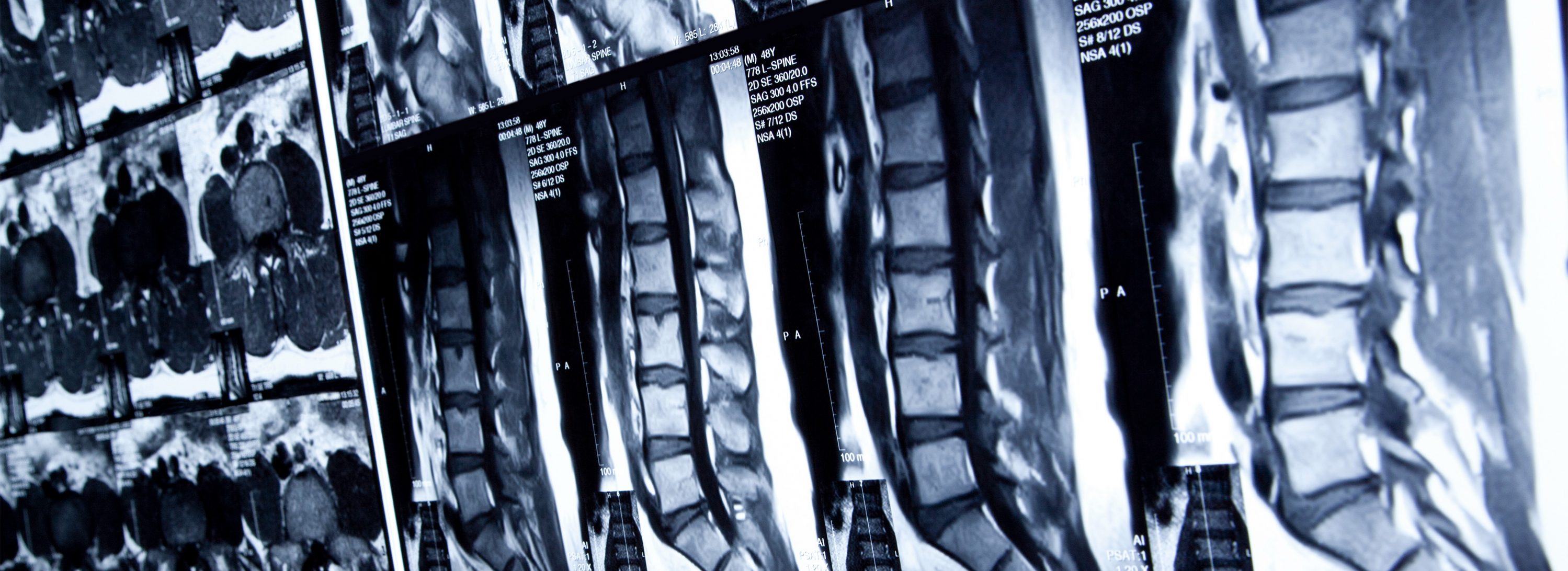

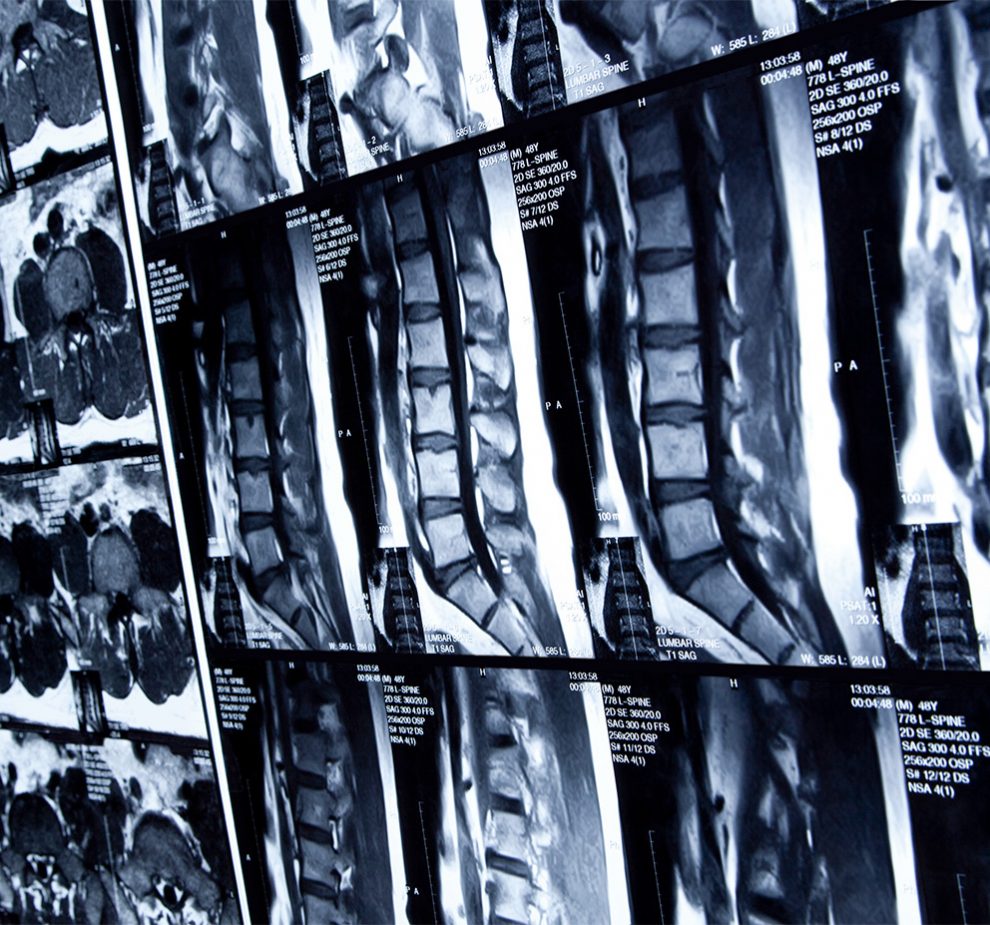

Collimators are commonly used to manage radiation in CT applications in two ways: by focusing a dispersive X-ray source into a manageable parallel beam that can be directed onto an area of interest, or by absorbing and attenuating scattered rays after they have emerged from the subject.

Collimators are also commonly applied in radiotherapy to shape the beam to match the shape of targeted cancer cells. As cancer therapeutics and radiotherapy become more sophisticated, tungsten and molybdenum collimators are finding increased use in medical applications that combine imaging and therapy such as external beam radiotherapy, nuclear medicine, and X-ray imaging.

Materials & Specifications

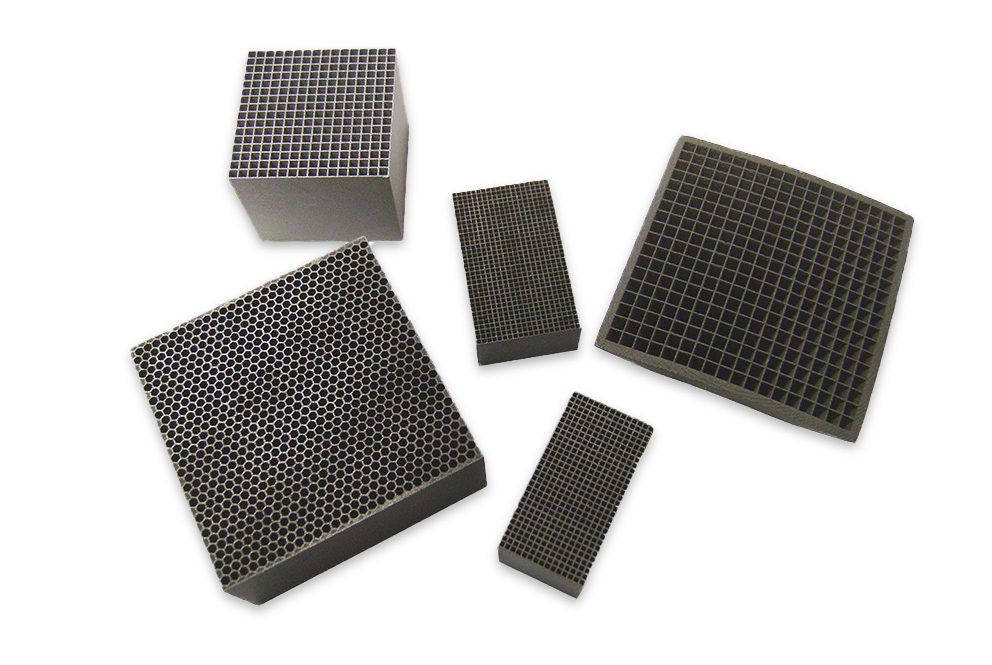

Pure tungsten and molybdenum sheet materials are often applied as an anti-scatter grid collimators as part of medical imaging detector assemblies. Elmet Technologies (formerly H.C. Starck Solutions) can precision roll such sheet materials to demanding thickness tolerances < 10mm and cut finished collimator blades to customer specifications.

Tungsten’s opacity to X-rays is ideally suited to radiation shielding applications in medicine. However, the extreme mechanical resilience of pure tungsten makes it difficult to work with. Adding nominal amounts of nickel, iron and/or copper into a tungsten matrix produces much more machinable alloys, suitable for producing intricate components for the medical sector.

As a world leader in refractory metal processing, Elmet Technologies (formerly H.C. Starck Solutions) can also manufacture precision tungsten alloy parts via additive manufacturing techniques, such as 3D screen printing. One example is in anti-scatter grid collimators for CT scanning that can improved image quality and reduce x-ray dosage to the patient. Such collimators can be produced accurately to high-resolution (~20 ), while high-capability inspection equipment ensures that all fabricated components are rapidly and reliably finished with contact-free quality assurance.

Elmet Technologies (formerly H.C. Starck Solutions) is the leading manufacturer of high-performance collimators for medical applications. To find out more about our collimators and other capabilities, complete the form below or contact your regional Elmet Technologies (formerly H.C. Starck Solutions) team via our contact page.

Related Brochures

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.